Version:2.0.09

: ${DateFormat('_systemdate')}$

Copyright © SMC Corporation. All Rights Reserved.comment

| Country (Area) | Language | |

|---|---|---|

| Japan | Japanese | Catalog |

| English language | Catalog | |

| Simplified Chinese | Catalog | |

| China | Simplified Chinese | Catalog |

| U.S.A. | English language | Catalog |

| South Korea | Korean language | Catalog |

| EU | English language | Catalog |

| German language | Catalog | |

| French language | Catalog | |

| Spanish language | Catalog | |

| Italian language | Catalog | |

| Polish | Catalog | |

| Czech | Catalog |

Product Specifications

| Product number: | |

| Series: | |

| Bore size: | |

| Maximum gripping force: | 外径把持->Fg_max,内径把持->Fn_max |

| Gripping point range: | 外径把持->DB2_Lg_min~Lg_max,内径把持->DB2_Ln_min~Ln_max |

| Maximum over hang: | 外径把持->Hg_max,内径把持->Hn_max |

| Maximum Opening/Closing stroke(Both sides): | |

| Opening/Closing Stroke(Diameter): | |

| Opening/Closing angle(Both sides): | |

| Width at opening: | |

| Width at closing: | |

| Weight: | |

| Internal volume (O port): | |

| Internal volume (S port): | |

| O port size: | |

| S port size: | |

| Operation Method: | |

| Finger: | |

| Gripping type: | 平行開閉外径把持->外径把持,平行開閉内径把持->内径把持,支点開閉外径把持->外径把持 |

| Fluid: | |

| Operating pressure: | |

| Ambient and fluid temperature: | |

| Repeatability: | |

| Max. operating frequency: | |

| Lubrication: | |

| Subject ⁄ Industry Classified ⁄ Specifications: | |

| Made to Order: |

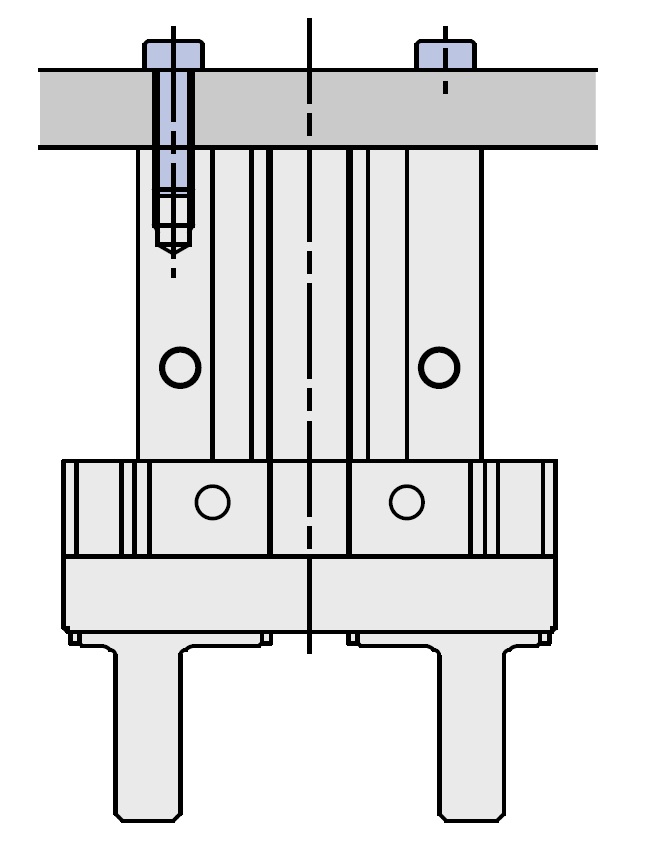

・The linear guide improves rigidity and accuracy. ・Dustproof and drip proof construction ・Dust cover material is selectable.

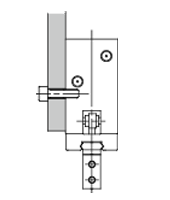

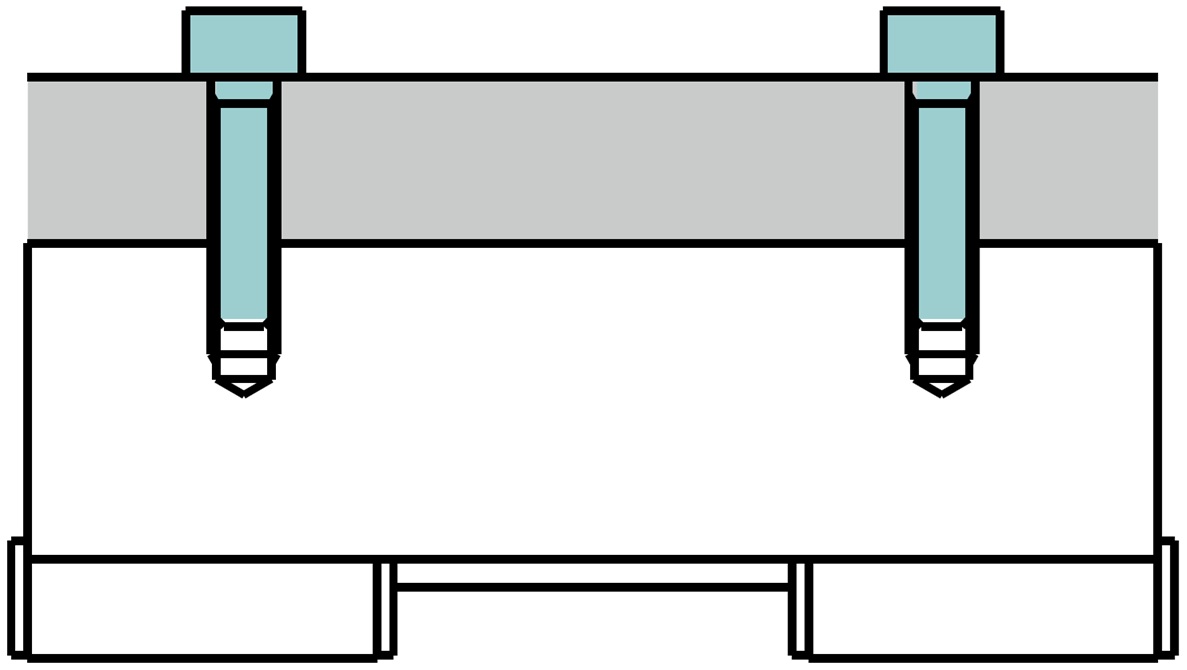

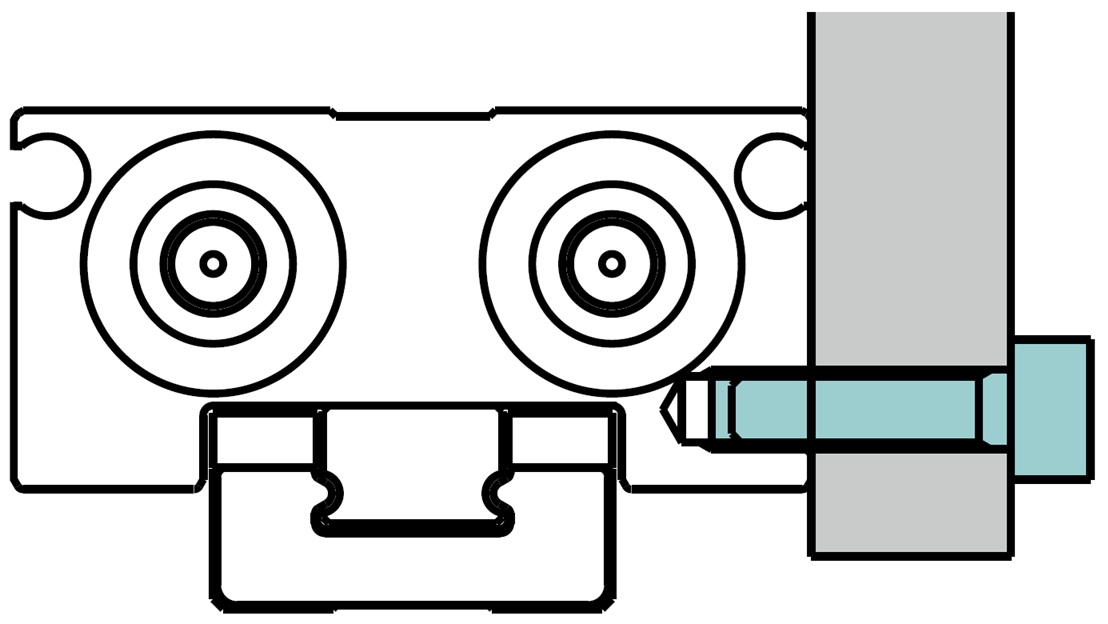

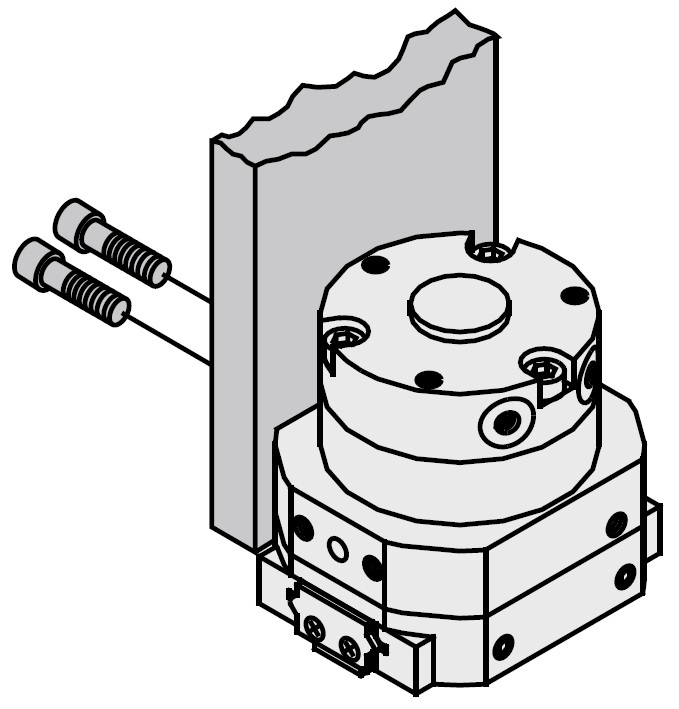

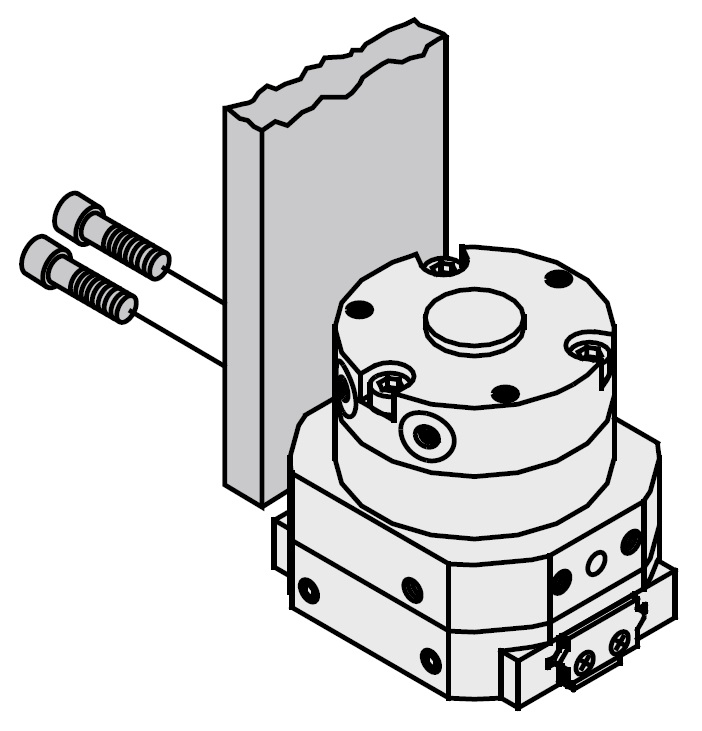

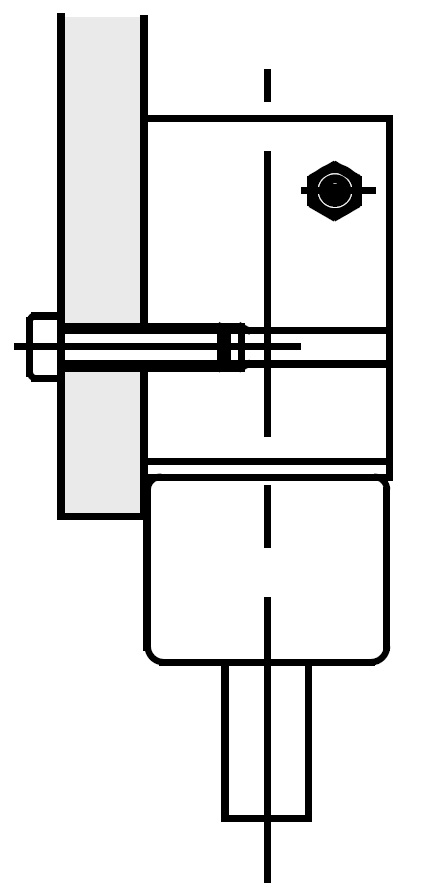

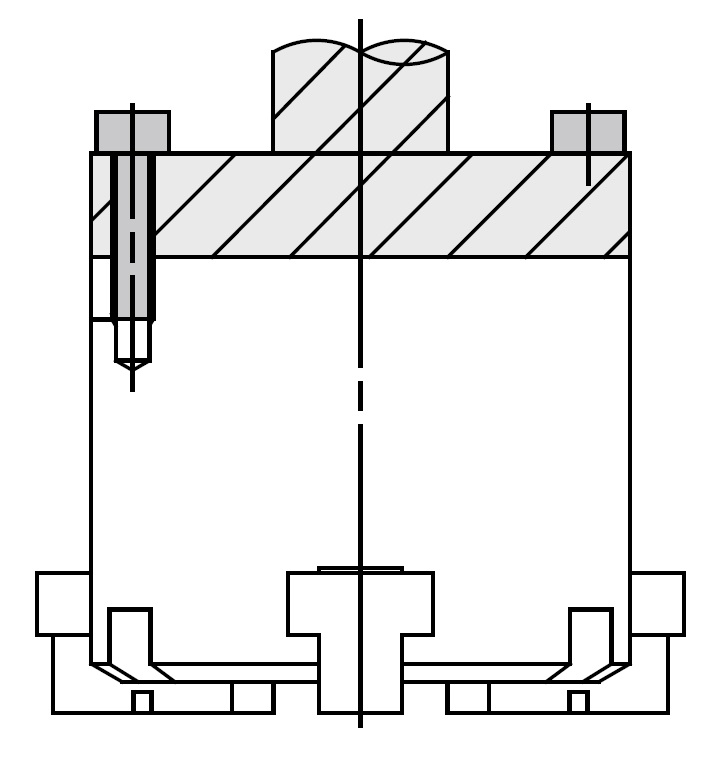

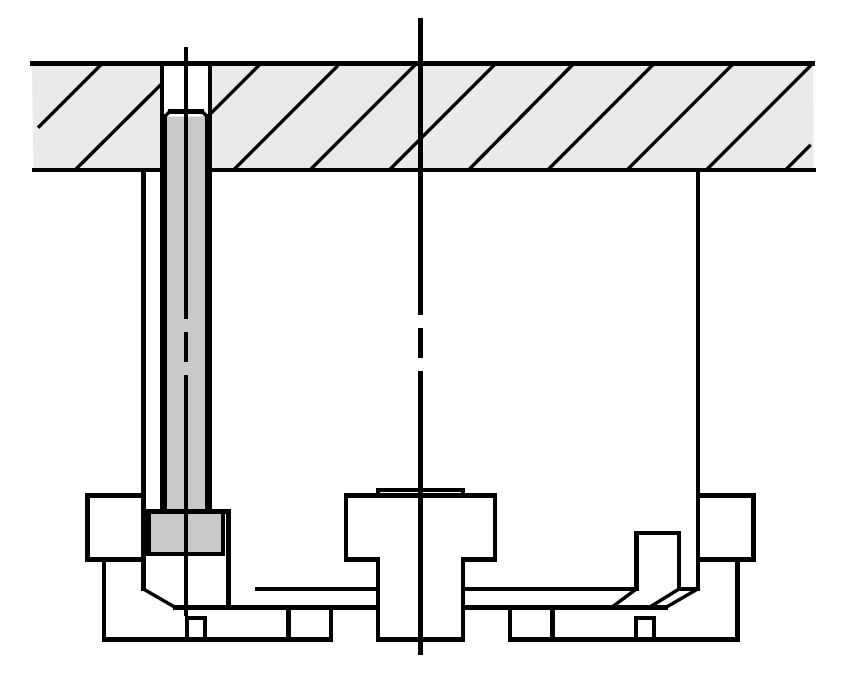

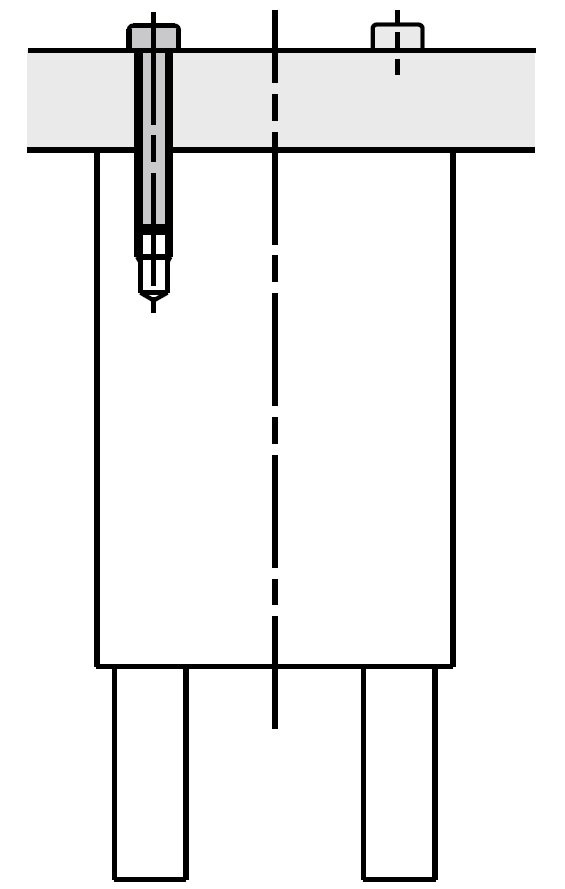

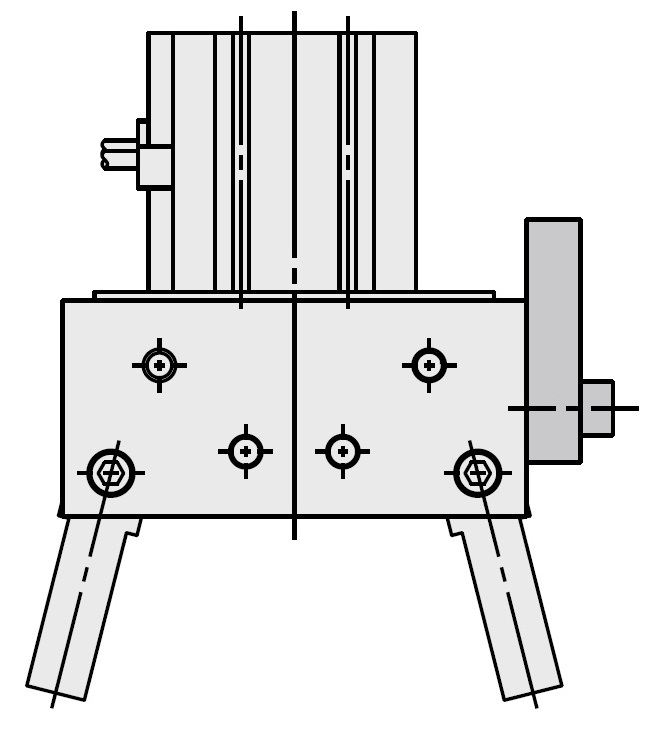

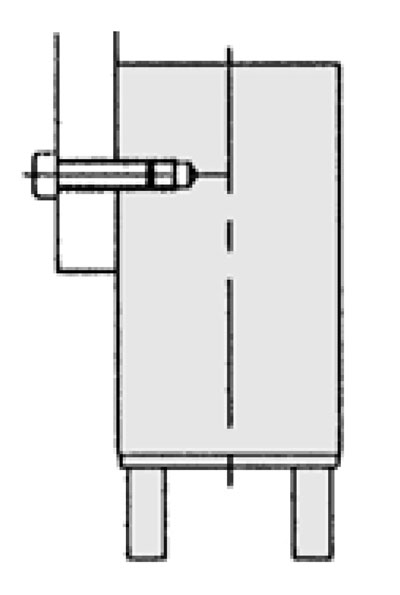

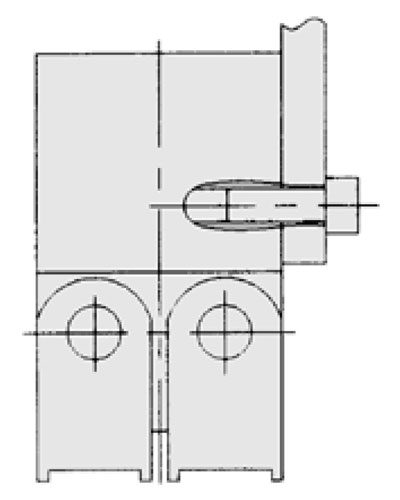

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

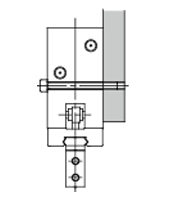

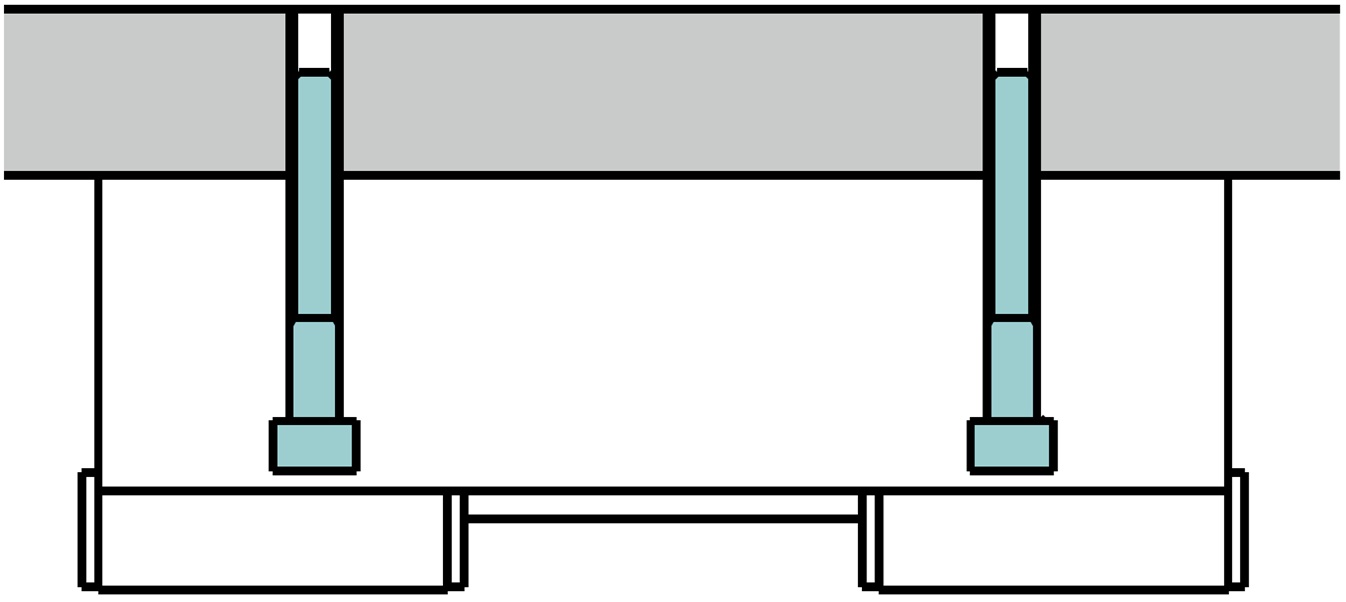

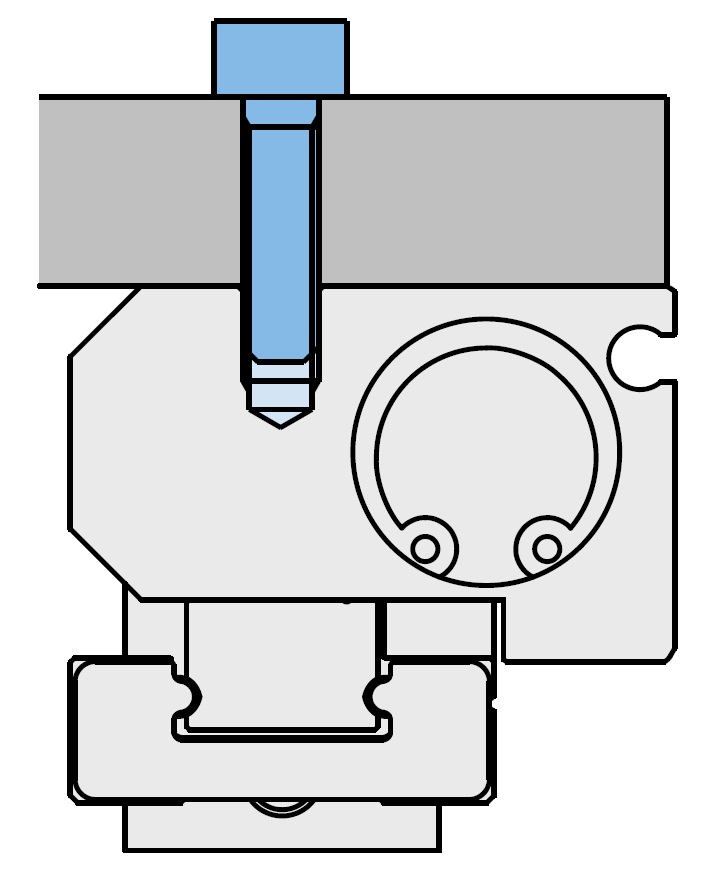

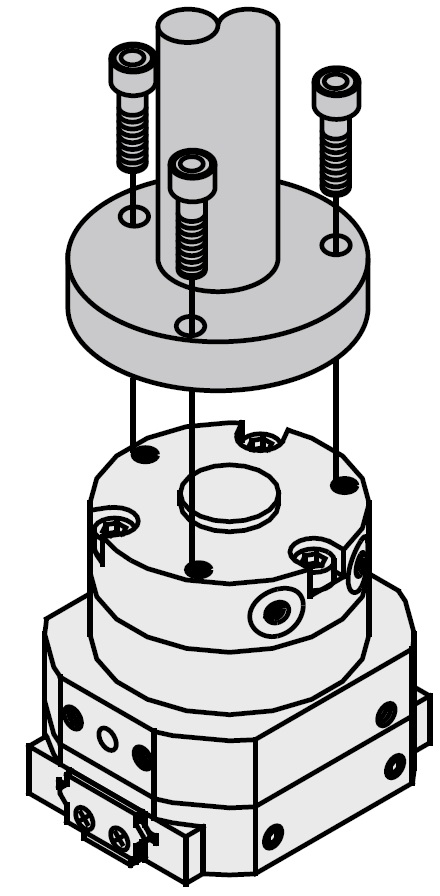

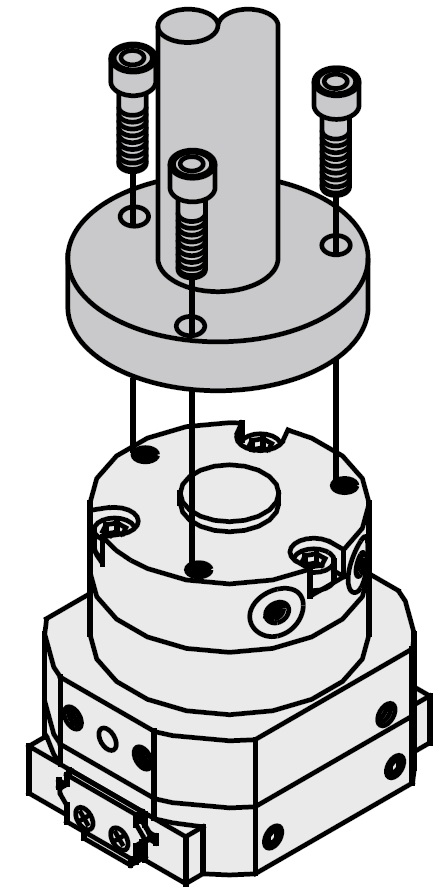

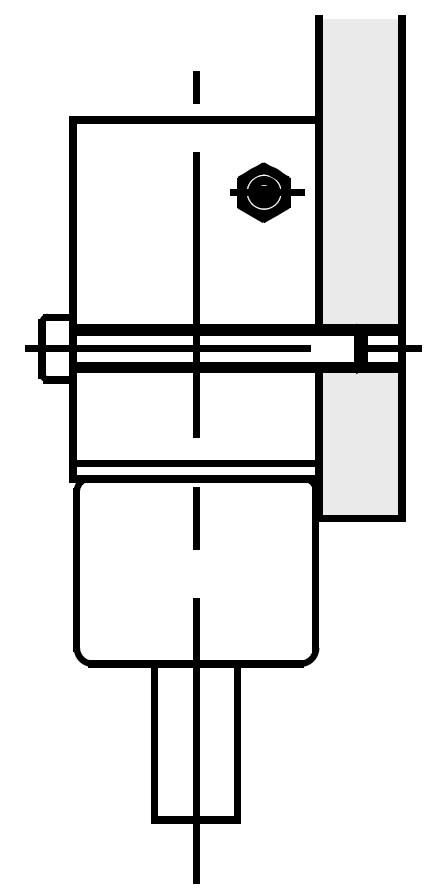

Axial mounting

Using end boss

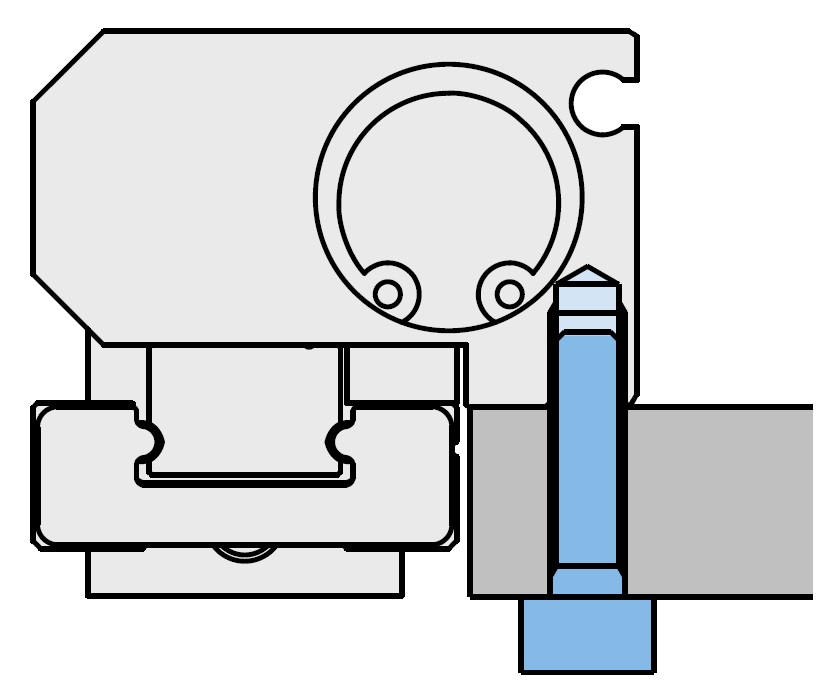

Axial mounting

Using tapped holes

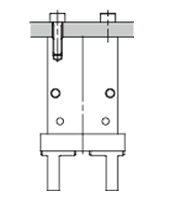

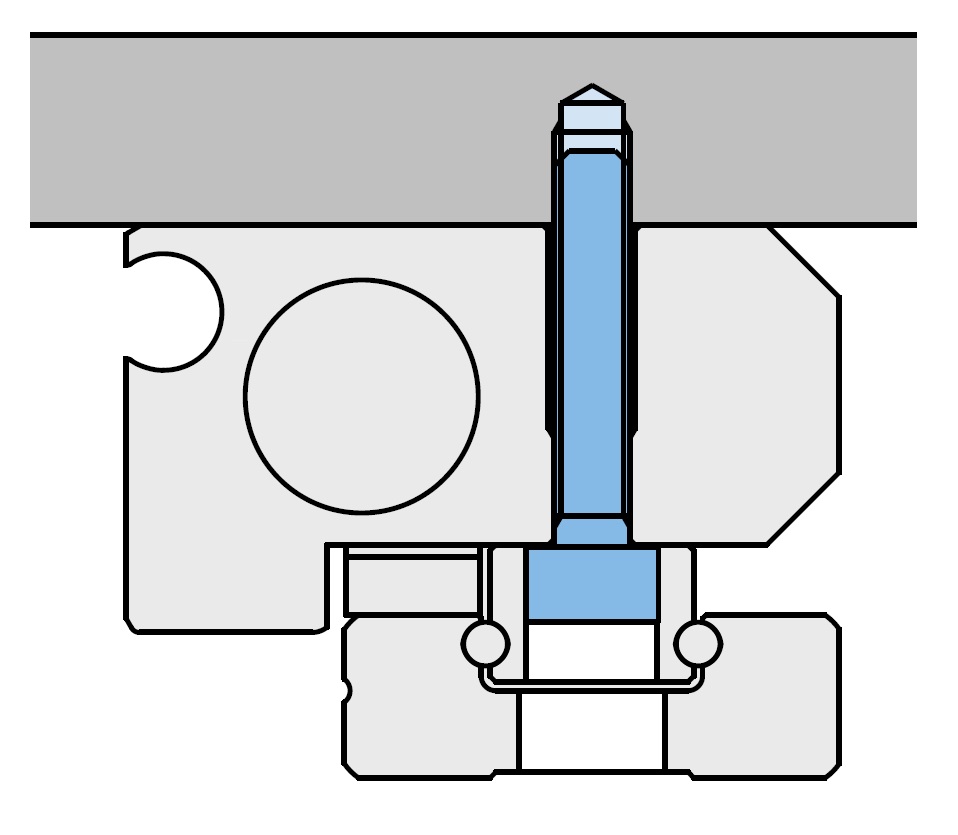

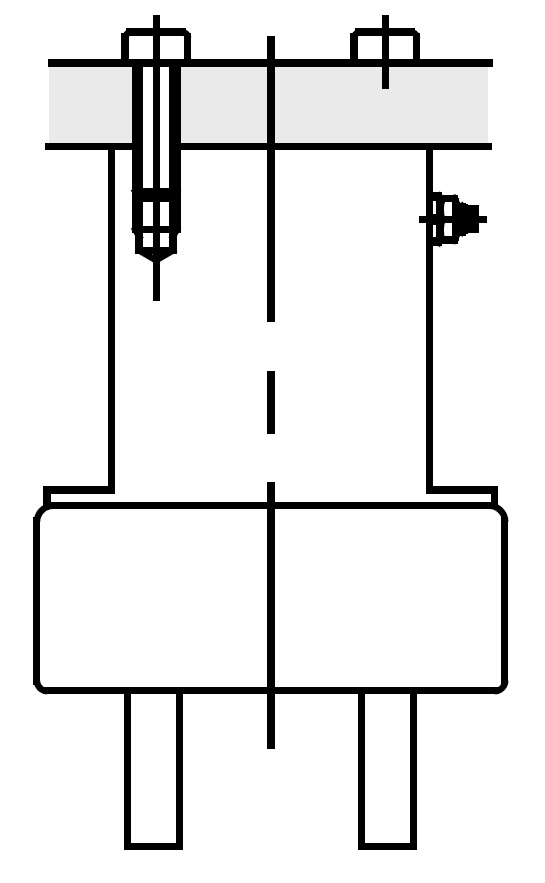

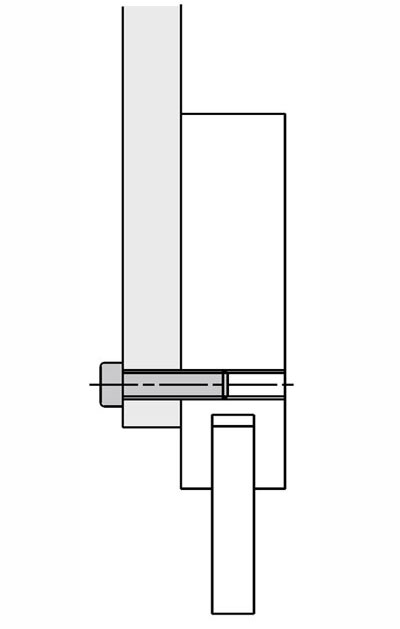

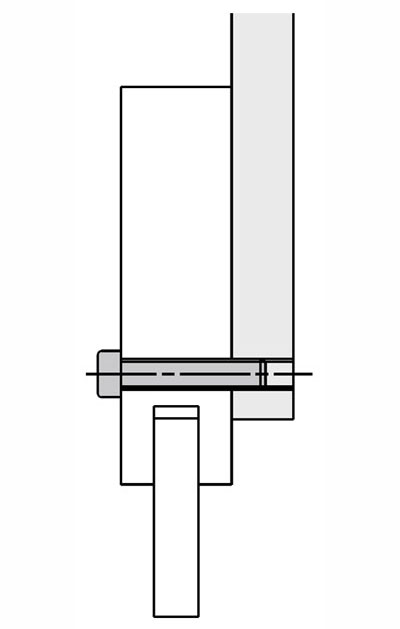

Vertical side mounting

Using tapped holes

・Downsizing is possible without changes to the gripping point range.(ø20→ø16) Overall length: Max. 21.7 mm shorter(102.7mm→81mm) Thickness: Max. 7.6 mm shorter(33.6mm→26mm) Weight: Max. 180 g lighter(420g→240g) ・High rigidity and precision are achieved by integrating the guide and finger. ・With high-precision linear guide Repeatability:±0.01mm ・A linear guide of higher rigidity and precision is used. Higher rigidity

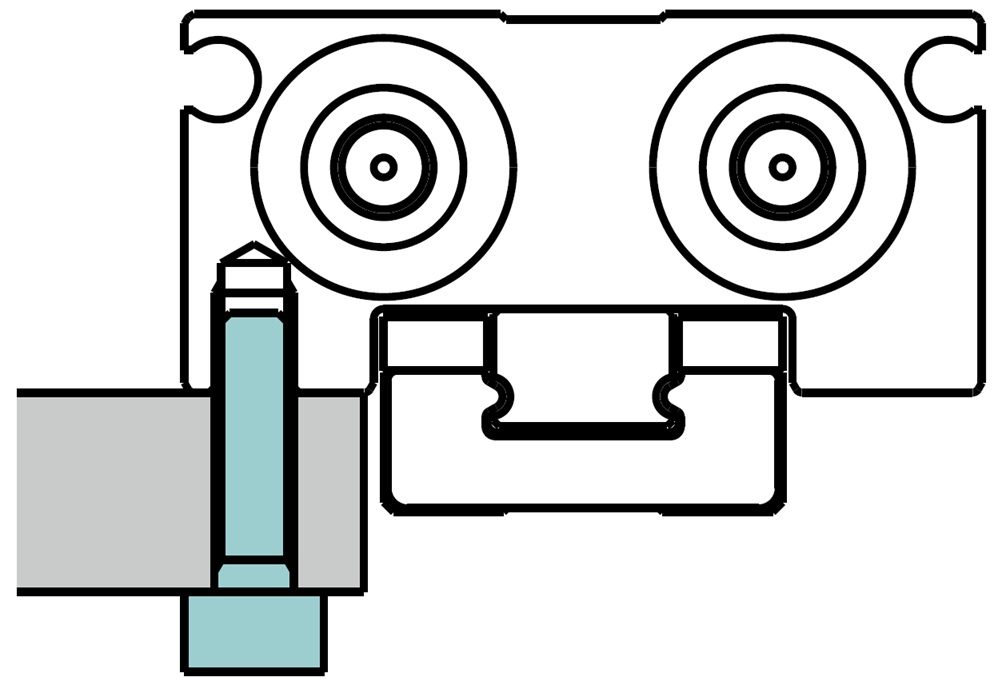

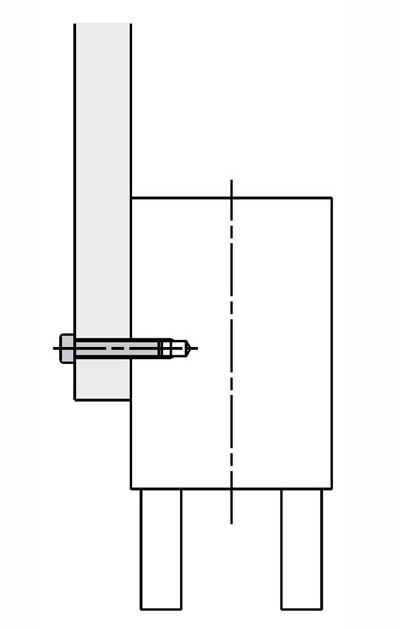

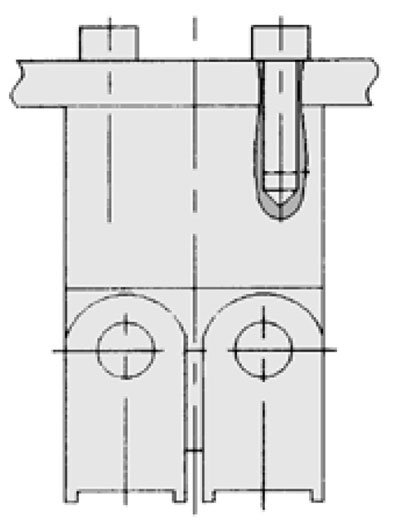

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

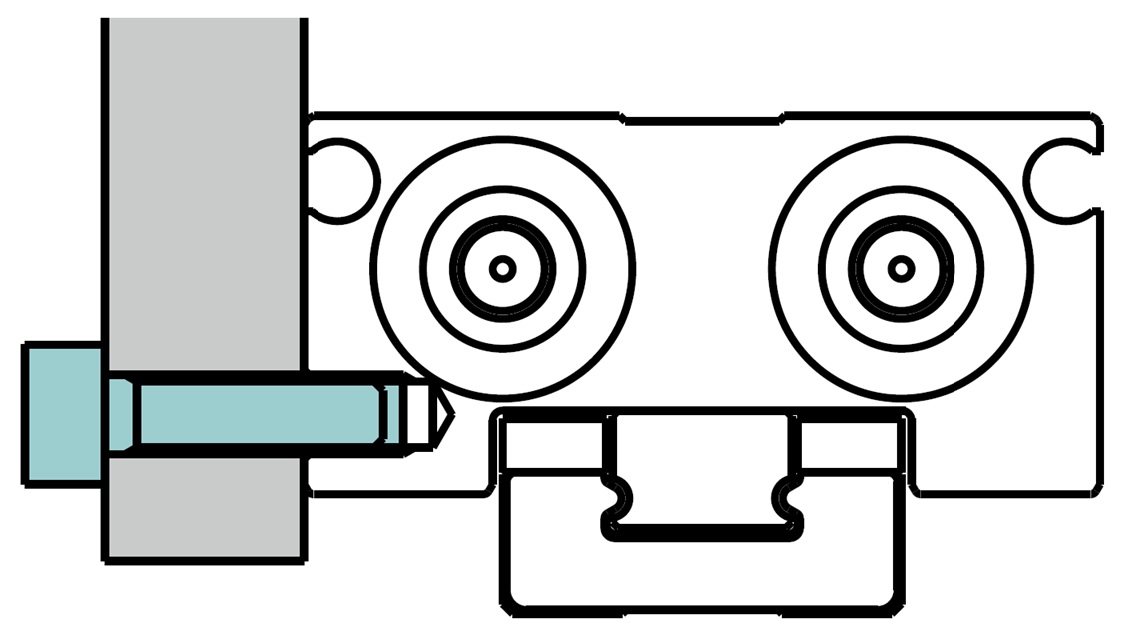

Axial mounting

Using tapped holes

・ø25 and ø32 have been added.High rigidity Gripping point distance: Max. 170 mm (For ø32, at 0.4 MPa) ・Height: Max. 66% reduction Moment reduction when transferring workpieces 72.8 mm → 25 mm (Comparison with our MHZ2 Series equivalent gripping force

products) ・3 types of strokes available for each size Short stroke, Medium stroke, Long stroke

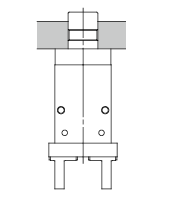

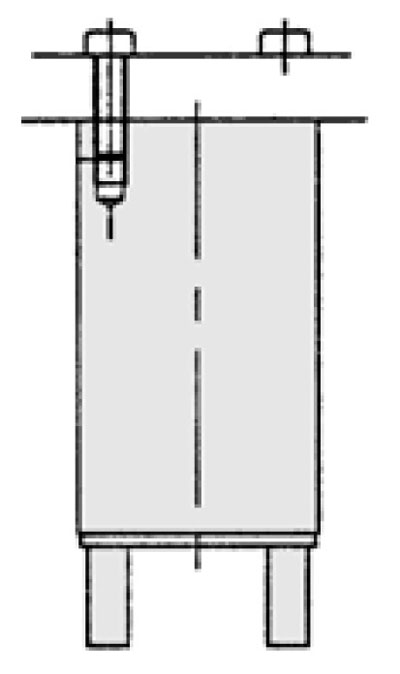

Bottom mounting

Using tapped holes

Bottom mounting

Using through-holes

Top mounting

Using tapped holes

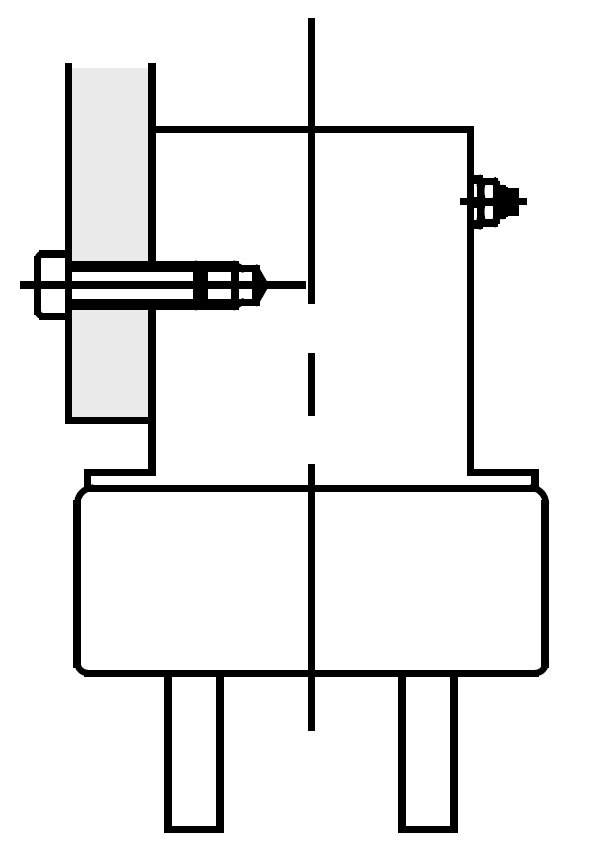

Side mounting

Using tapped holes

Side mounting

Using tapped holes

・Width: Max. 25% reduction(40mm→30mm) ・Weight: Max. 25% reduction(275g→205g) ・The fixed finger can be set to a reference position. ・Fixed finger position adjustment function

Bottom mounting

Using tapped holes

Top mounting

Using tapped holes

Bottom mounting

Using through-holes

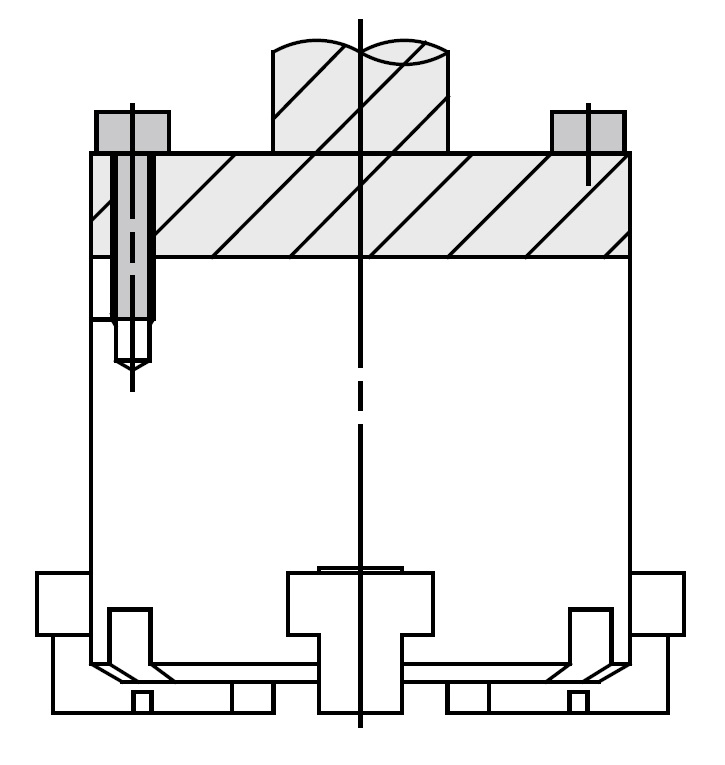

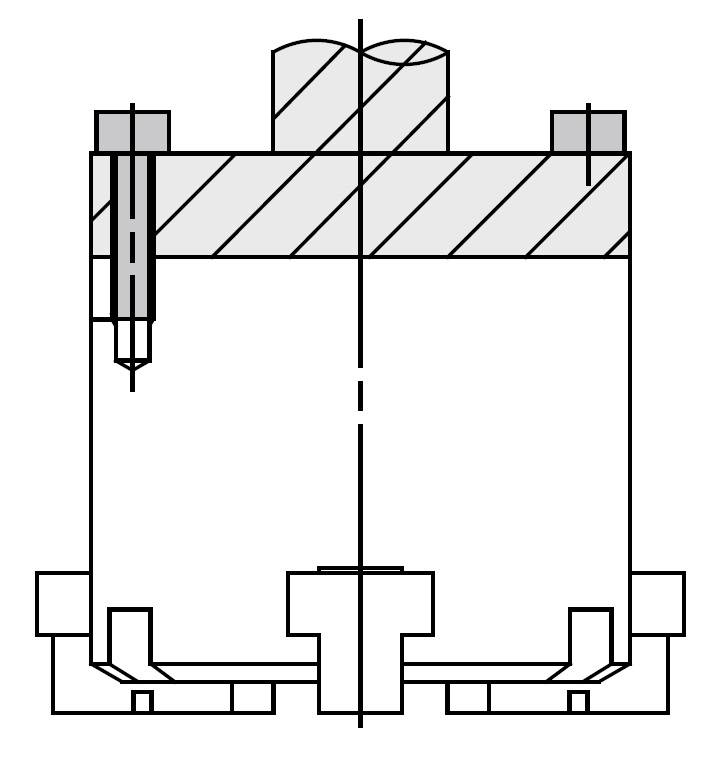

・Long strokes ・Ideal for holding large-size workpieces that have dimensional variances ・The double pistons provide a large amount of gripping force. ・Built-in dust protection mechanism

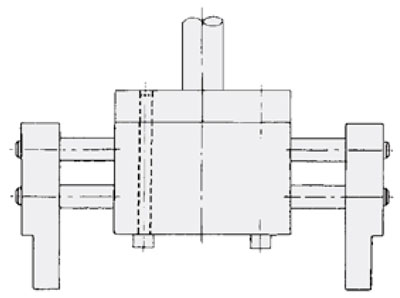

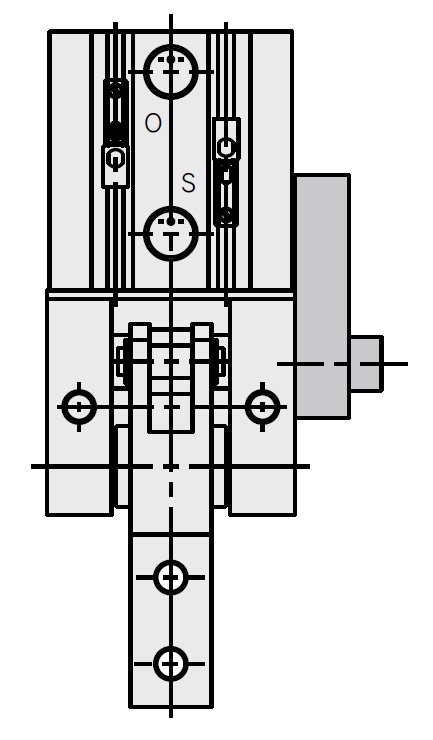

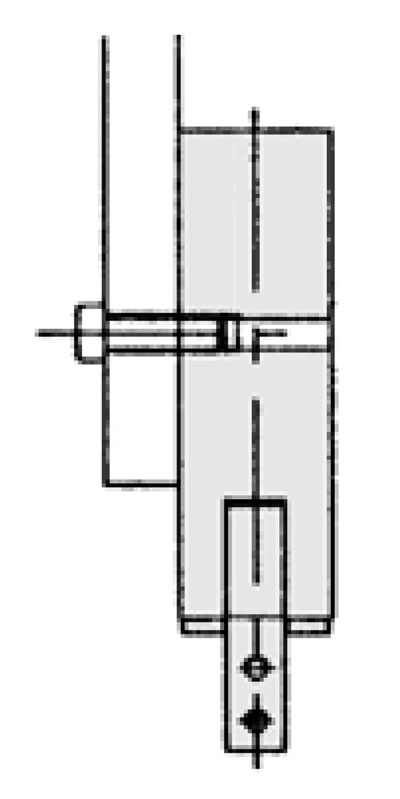

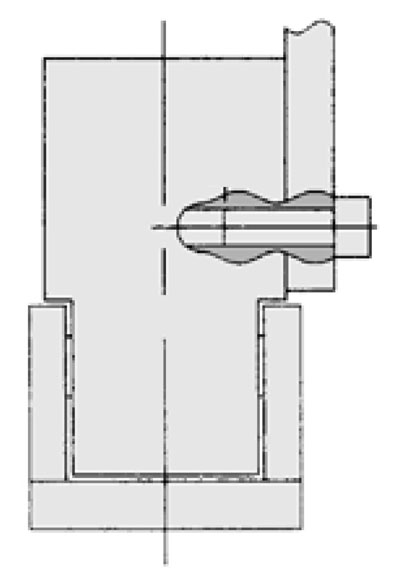

Axial mounting

Using tapped holes

Axial mounting

Using through-holes

Lateral side mounting

Using tapped holes

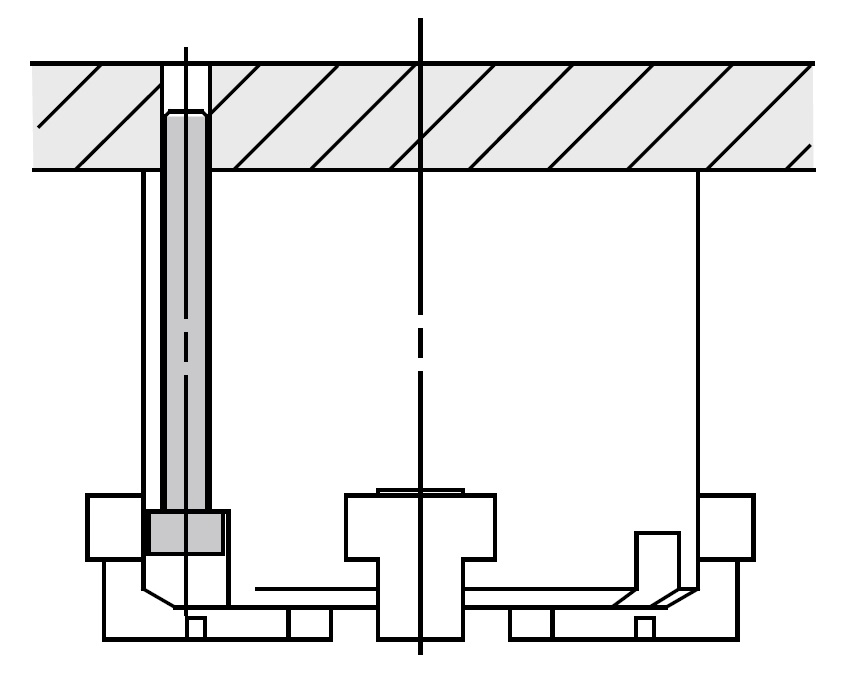

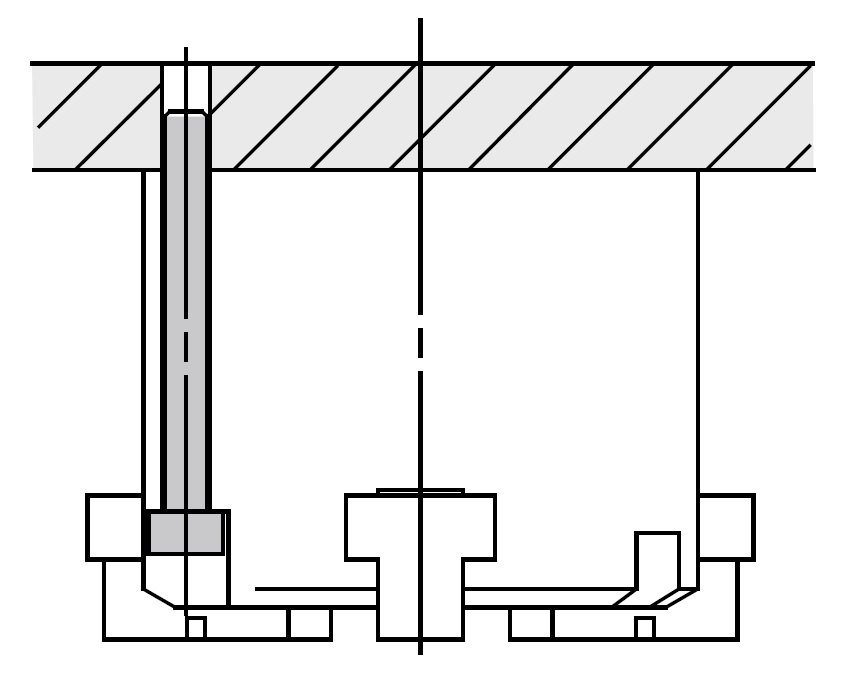

・Lightweight: Max. 10% lighter:585g → 525g Weight reduced by changing the body shape and internal construction ・Built-in dust protection mechanism (Standard) Dust-resistant option (Made to order: -X85, -X86□) ・Long stroke: One unit can handle workpieces of various diameters. ・A large amount of gripping force is provided, through the use of a double pistonmechanism, while maintaining a compact design. ・Small auto switches can be directly mounted.

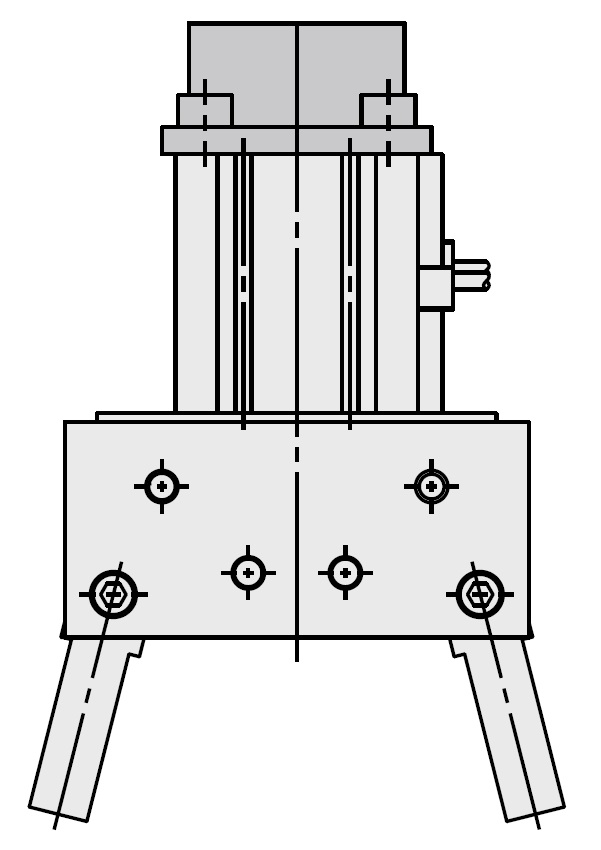

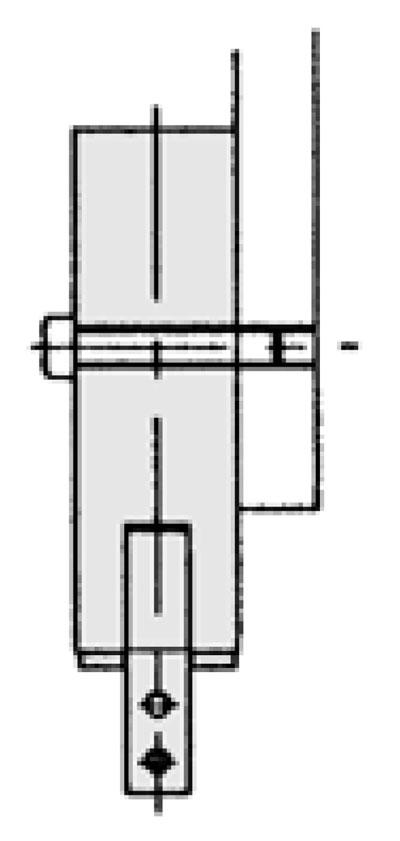

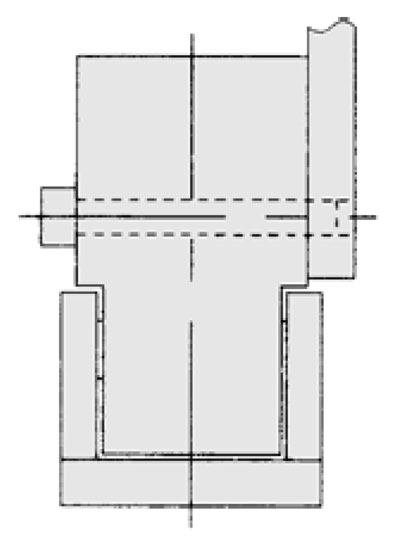

Axial mounting

Using tapped holes

Axial mounting

Using through-holes

Lateral side mounting

Using tapped holes

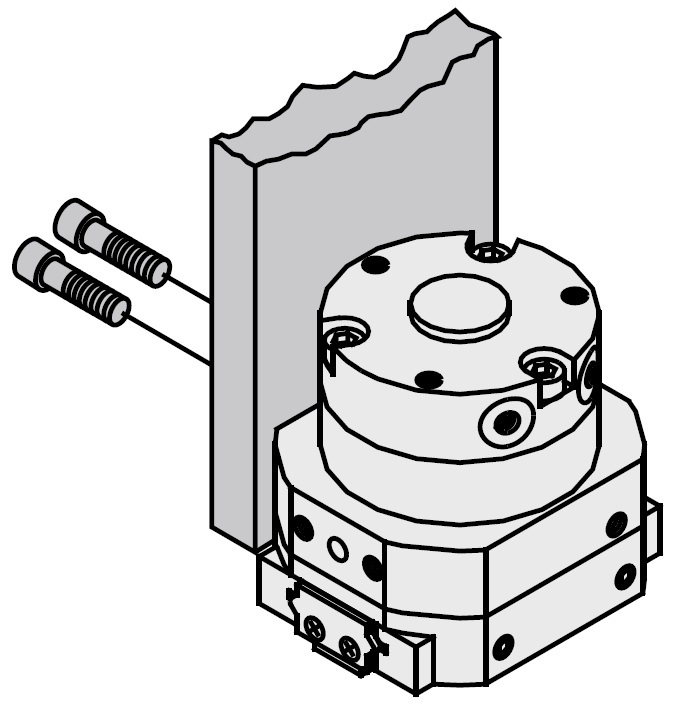

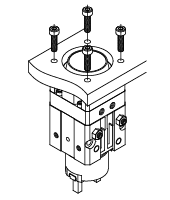

・A vertically compact configuration has been achieved through the use of a rotary actuator as the drive force source. ・Repeatability ±0.01mm ・Supports class 10 clean rooms ・With auto switch (MDHR2 series: MDHR2)

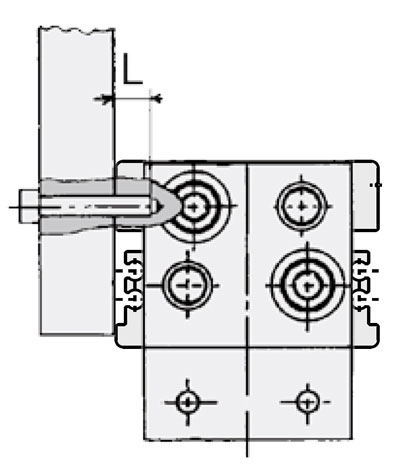

Lateral side mounting

Using tapped holes

Vertical side mounting

Using tapped holes

Axial side mounting

Using tapped holes

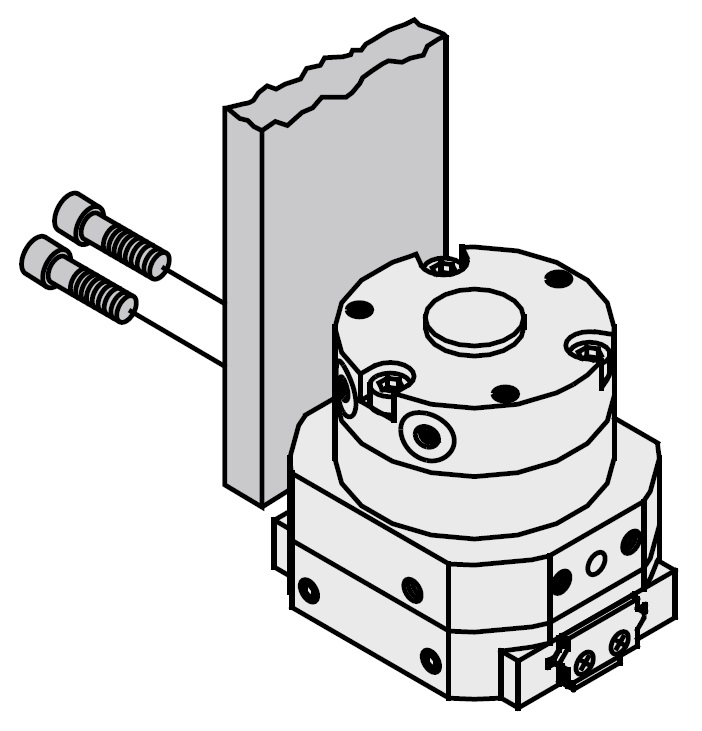

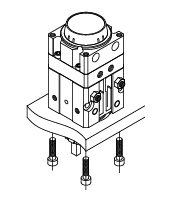

・A vertically compact configuration has been achieved through the use of a rotary actuator as the drive force source. ・Repeatability ±0.01mm ・Supports class 10 clean rooms ・With auto switch (MDHR3 series: MDHR3)

Lateral side mounting

Using tapped holes

Vertical side mounting

Using tapped holes

Axial side mounting

Using tapped holes

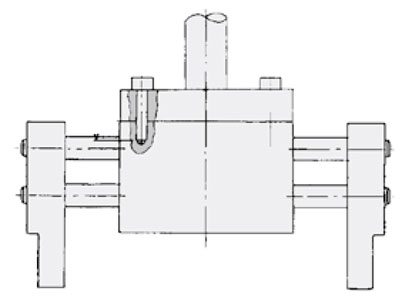

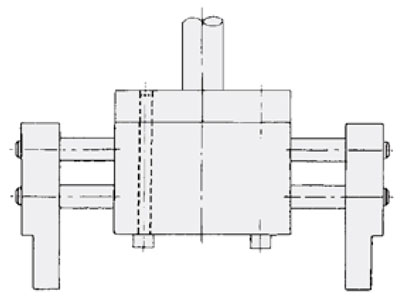

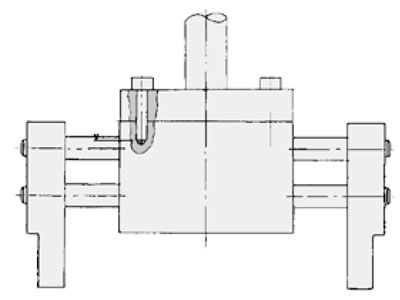

・Wedge shaped cam driving mechanism ・High rigidity with a slide type guide ・A dustproof, drip proof, external force resistant, and environmental resistant type that can be used for a variety of applications ・To suit the environment, a selection of dust cover materials (chloroprene rubber, fluororubber, silicone rubber) and stainless steel (SUS304) fingers are available. ・Long stroke option is selectable.

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

Axial mounting

Using tapped holes

Vertical side mounting

Using tapped holes

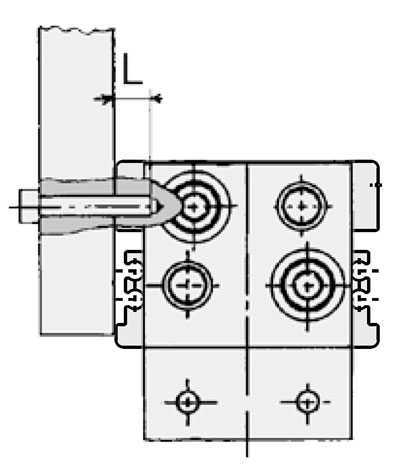

2 Fingers: ・Vertically compact and lightweight due to the wedge shaped cam construction ・Ideal for operations in which external force is applied, such as press ・Repeatability ±0.01mm

Axial mounting

Using tapped holes

Axial mounting

Using through-holes

3 Fingers: ・Vertically compact and lightweight due to the wedge shaped cam construction ・Ideal for operations in which external force is applied, such as press ・Repeatability ±0.01mm ・Long stroke type: Strokes 2 times longer than the standard type ・Gripping of cylindrical workpieces ・Reliable removal of the workpiece with through-holes and a center pusher

Axial mounting

Using tapped holes

Axial mounting

Using through-holes

4 Fingers: ・Vertically compact due to its wedge shaped cam construction ・Optimally holds rectangular workpieces for positioning operations ・Repeatability ±0.01mm ・Positioning of rectangular workpieces

Axial mounting

Using tapped holes

Axial mounting

Using through-holes

・MHC2-6:Auto switch mountable ・MHCA2-6:Short body ・MHCM2-7:Compact, lightweight ・A large holding moment is achieved through a double piston construction. ・Integral variable throttle

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

Axial mounting

Using tapped holes

Vertical side mounting

Using tapped holes

・The new cylinder body allows small auto switches to be mounted on 4 surfaces. ・A strong and stable gripping force can be obtained through the toggle mechanism. ・Holds workpiece even when the air is shut down (Safety measure)

Lateral side mounting

Using tapped holes

Axial mounting

Using tapped holes

Vertical side mounting

Using tapped holes

・Lightweight and compact through the use of a cam mechanism

Axial mounting

Using tapped holes

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

Vertical side mounting

Using tapped holes

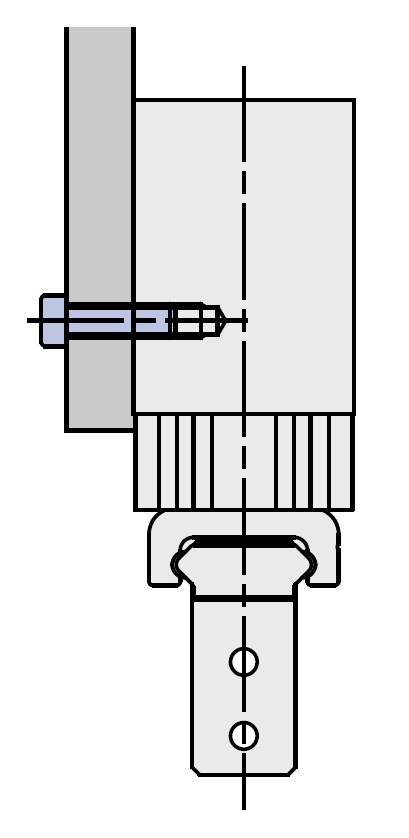

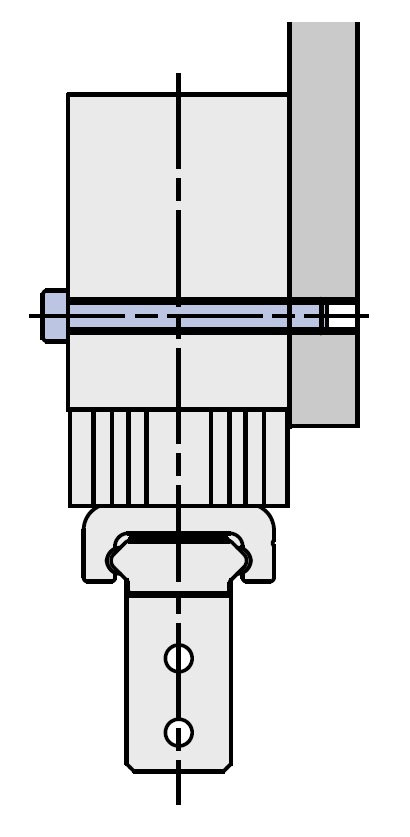

・Features a unique seal construction with a shortened overall length and dust proofing countermeasures that allow it to be used for removing workpieces from machine tools or for holding workpieces

Axial mounting

Using tapped holes

Lateral side mounting

Using tapped holes

Lateral side mounting

Using through-holes

Vertical side mounting

Using tapped holes

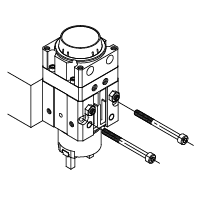

・The gripper function and the rotation function have been integrated in a compact package. ・It is possible to grip and reverse workpieces in conveyor lines with a single unit. ・Rotation range and angle are adjustable.

Bottom mounting

Using tapped holes

Top mounting

Using tapped holes

Front mounting

Using through-holes

Side mounting

Using tapped holes

・Products compatible with the environments of the secondary battery manufacturing process are available, contributing to the improvement of productivity and reduced defects. ・25A-MHZ2 ・25A-MHF2 ・25A-MHL2 ・25A-MHS ・25A-MHY2

・${クリーン環境に対応。

・${クリーンルーム内への発塵を防止。

・11-MHZ2

・11-MHL2

・11-MHR

・Suitable for environments where the presence of copper, fluorine or silicone materials is restricted. ・Structures are identical to the Clean Series. ・22-MHZ2 ・22-MHL2 ・22-MHR

・Suitable for environments where the presence of copper or fluorine materials is restricted. ・Dimensions are the same as those of the standard model.